Professional Use Only

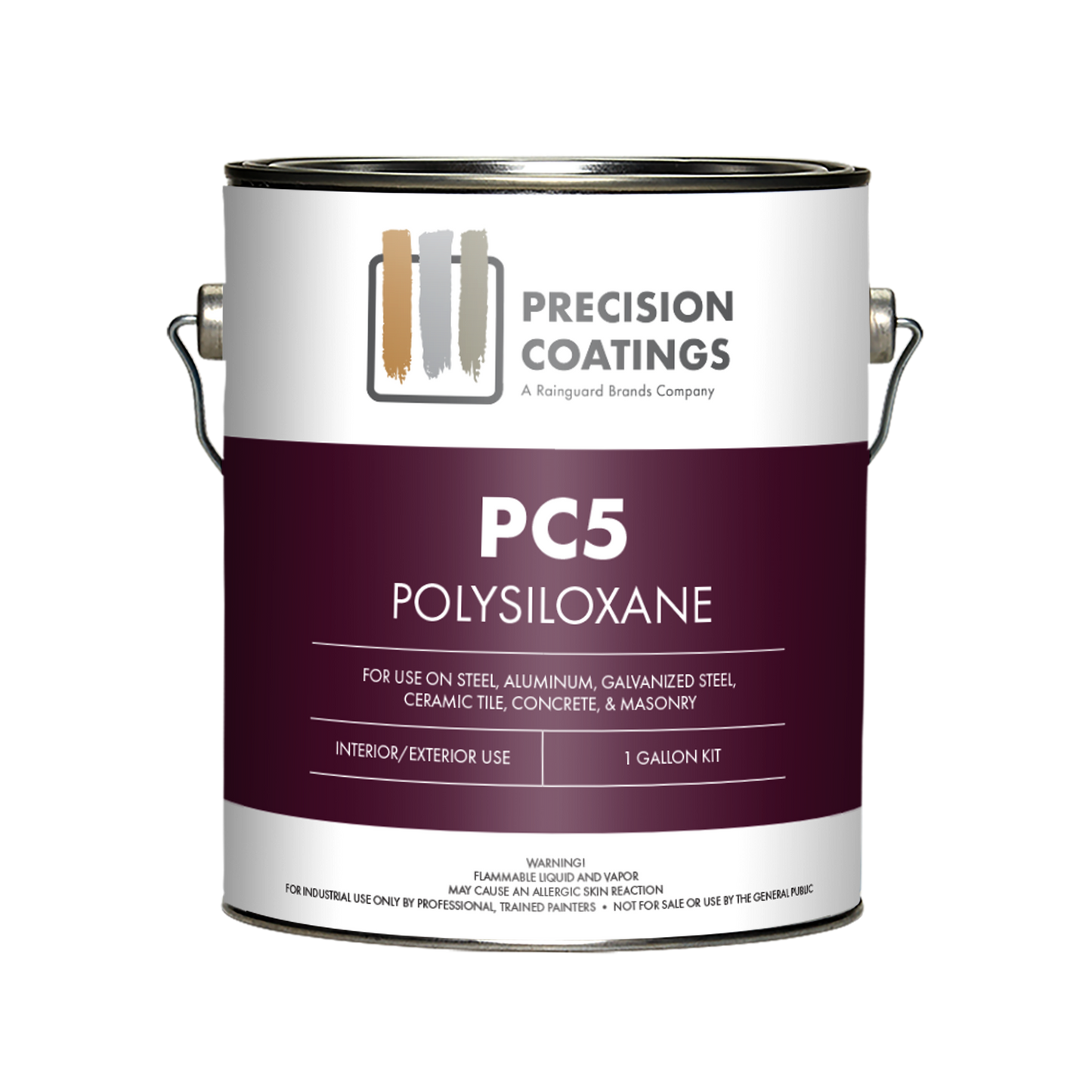

PC5 Polysiloxane

PC5 Polysiloxane

PC5 Polysiloxane is a very durable, high-quality 3rd generation polysiloxane finish that offers superior flexibility, gloss retention and color retention. It provides a stain-resistant, easily cleaned, graffiti resistant, low odor, low VOC coating system for interior and exterior surfaces.

Share

Surface Types

Surface Types

- Steel

- Galvanized Steel

- Aluminum

- Ceramic Tile

- Concrete

- Masonry

See Technical Data Sheet for full details.

Coverage

Coverage

RECOMMENDED DRY FILM THICKNESS: 3-5 mils per coat (75-125 microns), 1 to 2 coats

THEORETICAL COVERAGE: 492 – 295 sq. ft. at recommended DFT (theoretical)

Finish

Finish

Available in Clear and Yellow Flash in Semi-Gloss finish and White in Gloss finish.

Primer

Primer

See Technical Data Sheet for full details on if/when a primer is needed.

Pot Life

Pot Life

4 hours @ 70° F, 21° C

Dry Time

Dry Time

Tack Free: 4 Hours

Dry Time: 24 Hours

Recoat: Full recoat 24 hours

See Technical Data Sheet for full details.

What Comes In A Kit?

What Comes In A Kit?

Part A: 3/4 Gallon

Part B: 1 Quart

Request a Quote

Contact your sales reps for quotes, problem solving advice, extensive technical knowledge, pricing, ordering and field support.

Projects

-

-

More projects coming soon...

Additional Information

Surface Preparation

PC5 Polysiloxane may be applied over appropriately prepared steel, aluminum, galvanizing, concrete, masonry, ceramic tile and coated surfaces. It may also be applied over appropriately primed substrates.

See Technical Data Sheet for full details.

Application

Apply using 40-55 PSI at the gun for siphon and gravity feed spray guns, 10 PSI max. at the air cap for HVLP spray guns.

Can also be applied with a natural bristle brush or a 1/4 to 3/8-inch nap, mohair or no-lint cover roller with a phenolic core.

NO FOAM ROLLERS.

See Technical Data Sheet for application details.

Clean Up

Clean all spray equipment immediately after use. Acetone may be used to clean spray equipment.

See Technical Data Sheet for full details.